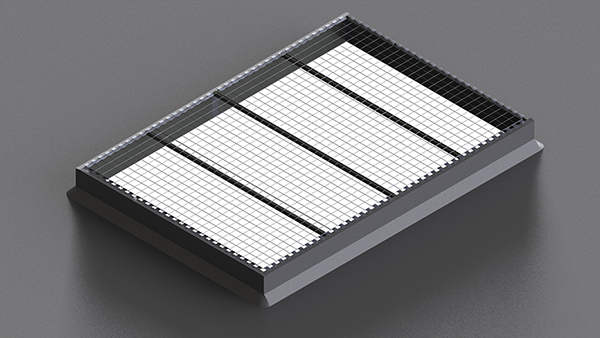

LAMILUX Continuous rooflight B

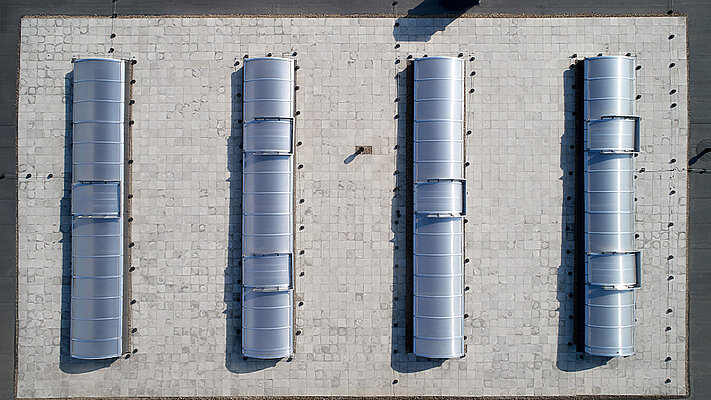

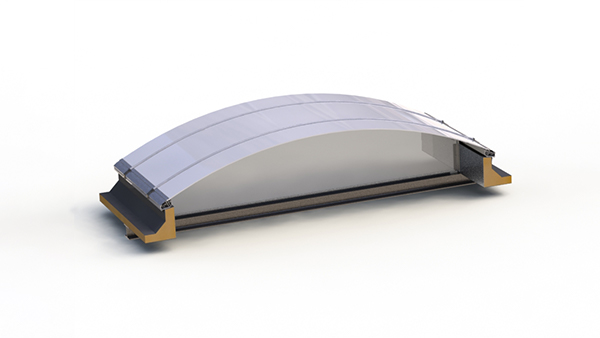

The world's first continuous rooflight with certified watertightness

Benefits at a glance

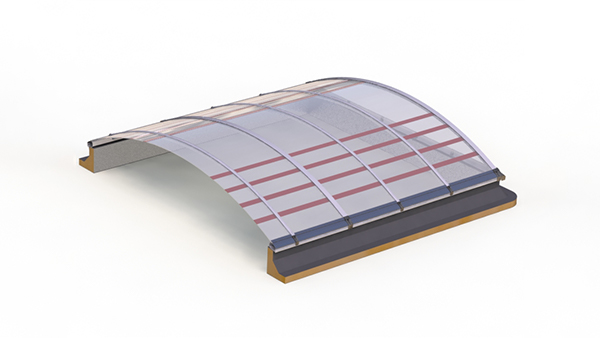

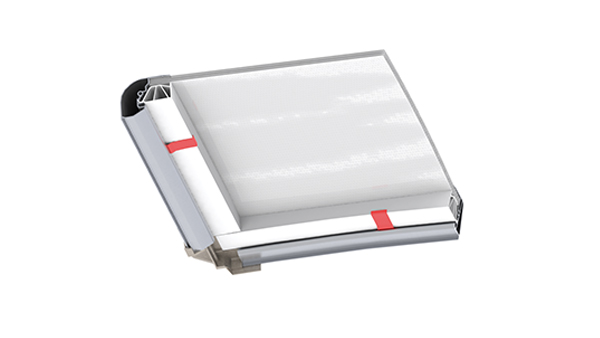

Continuous Rooflight B

Energy efficiency

- NEW: First Continuous Rooflight on the market with tested air tightness up to class A according to ETA 09/0347

- Integrated, modular system which consists of many perfectly matched and innovative individual components

- Perfect heat insulation with European approval for use

- The internal and external metal components, both in the load-bearing structure and in the flap systems, are completely thermally separated from one another

- Use of the isothermal load converter (ITL) – a component for the use of material with excellent heat insulation properties at the anchor point

- Composite glazing with extremely low thermal transmittance coefficients

- LCA made easy: For our Continuous Rooflight B there is an comprehensive product declaration according to ISO EN 15804

Stability

- NEW: design snow load up to 4.4 kN/m² (according to Eurocode)

- NEW: with our GFUP glazing, a composite material made of glass fibres and polyester resin, we achieve hail resistance class HW5 according to the VKF guideline

- Thanks to our Composites Division and the associated expertise, our GFUP glazing is particularly resistant to UV radiation, weathering and chemically aggressive emissions

- The world's first Continuous Rooflight with audited watertightness under heavy rain and storm (DRI 3.0 m/s²)

- Our Continuous Rooflight B is BIM-ready - download at bimobject.com

- Extremely stable when open guaranteed by spring-loaded multiple joint traverses connected directly to the flap construction

SHEV

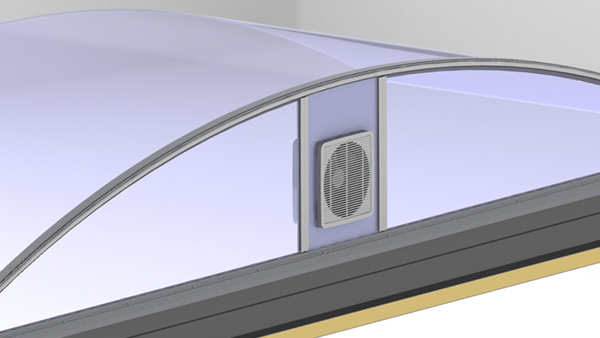

- NEW: SHEV and ventilation drive now also available as 48 volt motor

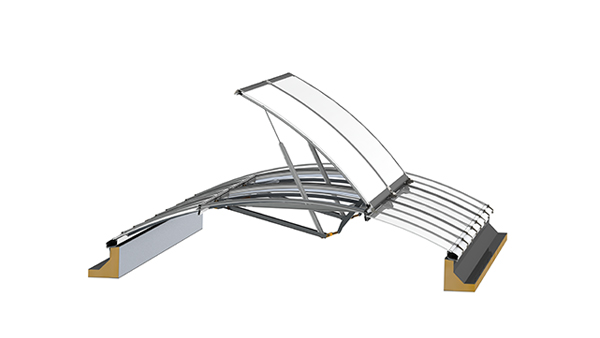

- Effective ventilating action with the Smoke Lift Continuous Rooflight B (DIN EN 12101-2), as a double or single flap

- In case of fire, they are quickly opened by means of thermal release, thermal and CO2 remote release or electric remote release

- All smoke and heat exhaust systems can also be combined with ventilation systems

Safety

- Fall-through-proof during installation, valid for 1 year after manufacture

- Optional: permanent fall-through protection can be ensured by various systems

- We maintain professionally and regularly for you

Variants

Continuous rooflight B

Glazing types

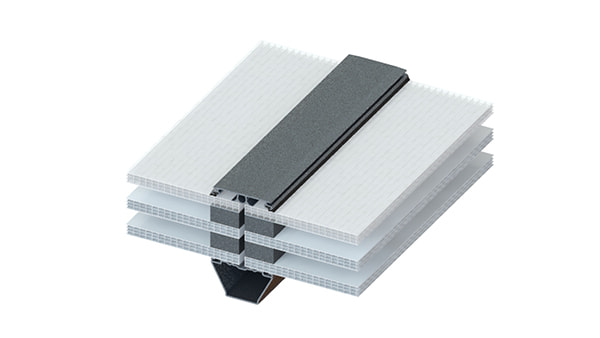

- Our own 32 mm thermal composite: Low flammability combined with excellent thermal insulation

- Optimum glazing for all requirements, such as sound and thermal insulation, light transmittance and chemical resistance

- Multi-layer, opal polycarbonate panels (glare-free) offered as standard

- Clear panels at no extra charge

- Possible to add sun protect (partly)

- "Hard roofing" possible – combined with melt-out surface

- GF-UP + GF-UP glazing variations upon request

Note: Ug value is determined per DIN EN 673 (vertical installation). The profile structure's actual heat transmission values, including those of base profiles, gable wall profiles and flap profiles, have to be used to calculate the Continuous Rooflight's energy values.

Flap systems for SHEV and ventilation

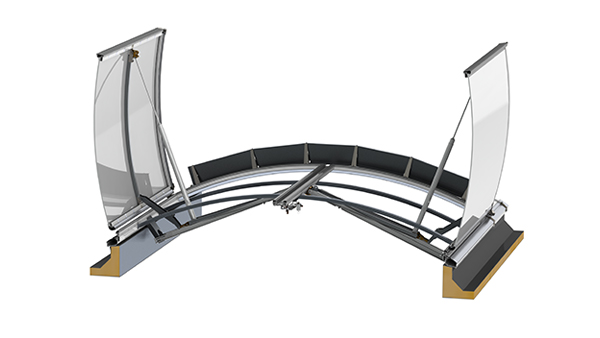

- Integration as single flap or flap-on-flap system

- Opening and closing is either manually-triggered or automated using the control system through electric motors (24 Volt/ 230 Volt) with a spindle drive or pneumatic drive assemblies with pneumatic cylinders

- Wind and rain sensor set

- Optional: energy-efficient, automated control of flap systems for natural ventilation

- Optimal impermeability to driving rain through welded sealing frame with anti-splash lip and an integrated balloon sealing

Large Ventilation Flap BE Single Flap

| Type | Opening surface Ageo |

|---|---|

| 100/100 | 0,93 m² |

| 100/200 | 1,96 m² |

| 125/100 | 1,17 m² |

| 125/200 | 2,26 m² |

| 150/100 | 1,43 m² |

| 150/200 | 2,45 m² |

Smoke Lift Continuous Rooflight B

Can be supplied as a single flap system or as symmetrical or asymmetrical double flap system (more information here)

Accessories

Continuous Rooflight B

"Hard roofing”

- The Continuous Rooflight B glazing meets the conditions for "hard roofing" and "melt-out area" at the same time – or comply with these two characteristics separately

- It meets the DIN 4102-7 requirements for flying sparks and radiating heat – as confirmed by MFPA Leipzig GmbH (Approval No. PZ III/B-05-028)

Attachment point for PPE

- Attachment point for personal protection equipment against the danger of falling.

- Installation on LAMILUX Continuous Rooflight frame prepared for this purpose

- Fastening point for the use of a karabiner in combination with safety harness (EN 361) and fall arrest system (EN 363)

- Mounting for max. 3 persons

Other available accessories: Assembly opening, roof exit hatch, partition wall, blower door

Technical details

Continuous Rooflight B

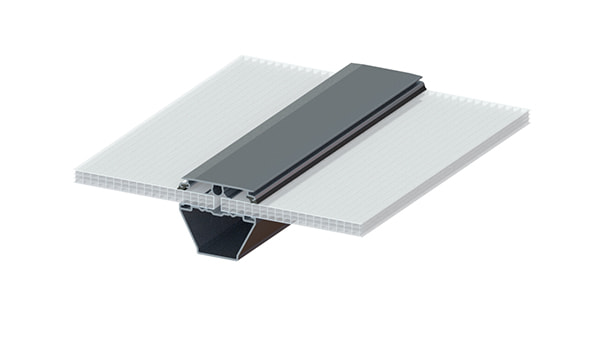

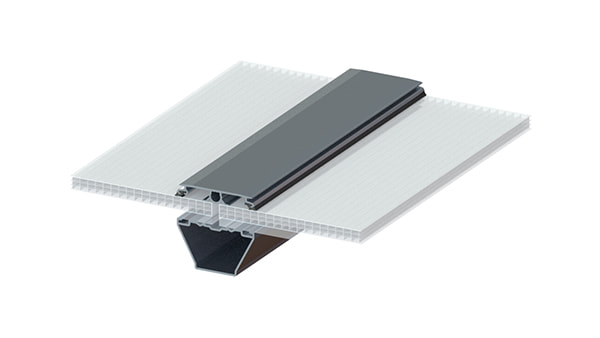

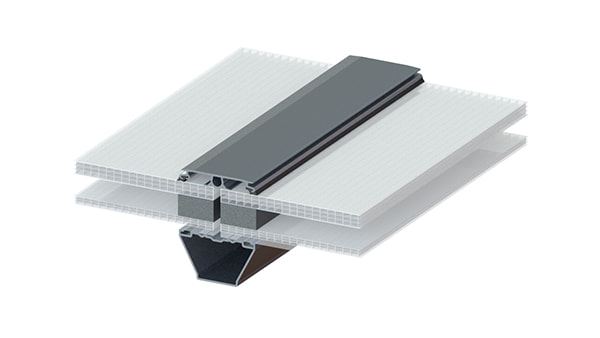

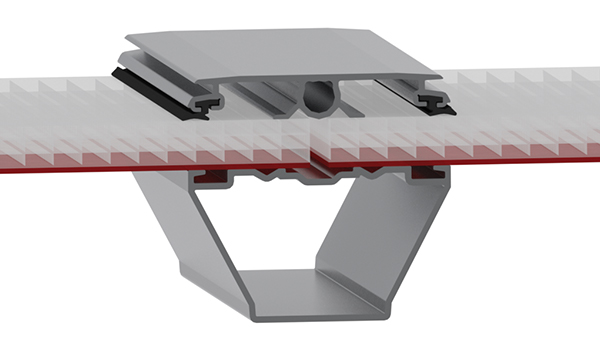

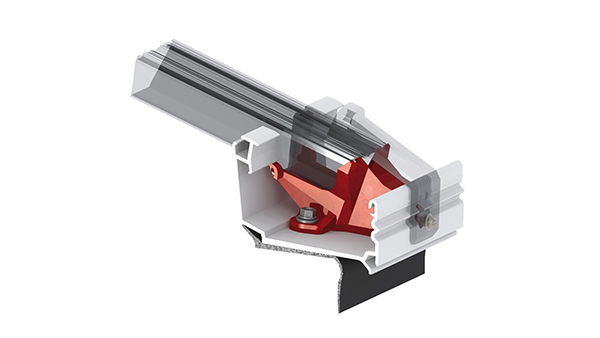

Dynamic torque control – DTC

Effect: Integrated suspension beneath the glazing bar in the mounting frame (DTC spring) ensures that the glazing is perfectly tensioned. It is therefore secured in position by a specific holding force even when subjected to load.

Benefit: The glazing remains perfectly tensioned and secured in all situations, as any acting loads are optimally cushioned and absorbed by the mounting frame.

Protection in the event of heavy wind loads

- High stability of flaps – even in opened condition

- Even better anchorage for polycarbonate glazing

- Additional flap system protection due to spring-mounted, multiple-joint traverses

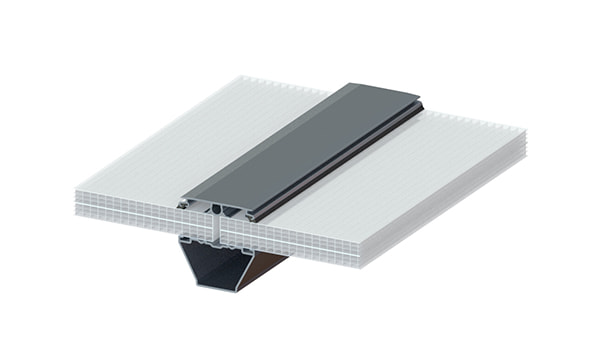

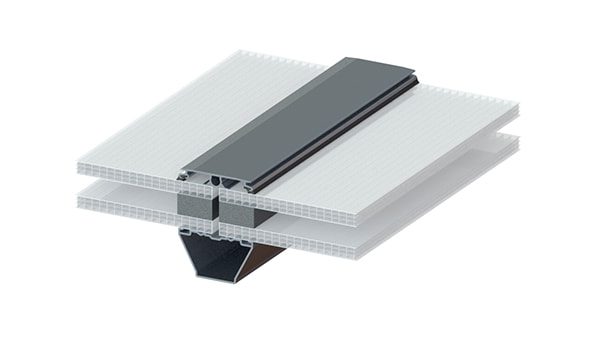

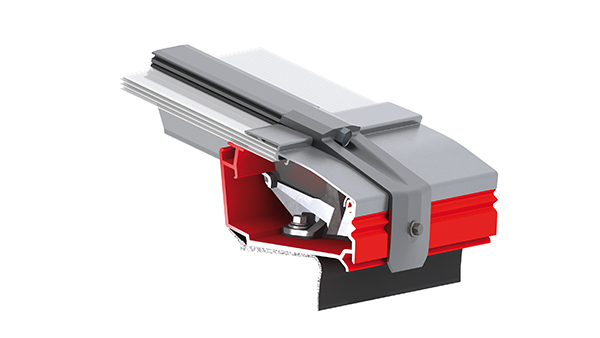

Active expansion absorber – AEA

Effect: The Active Expansion Absorber compensates the tension and expansion which occurs when under loads. This is achieved through the continuous, shear-resistant connection between the seals and the cover strips.

Benefit: Optimal protection of the construction in the event of snow, ice, wind and excessive heat development.

Safety aspects in detail

- The glazing is watertight and is positively fitted to the cover strips and glazing bars.

- The cover strips have integrated guide rails for mounting fittings, sun protection devices and maintenance equipment.

- The clamp is made even safer through an extended adhesive area.

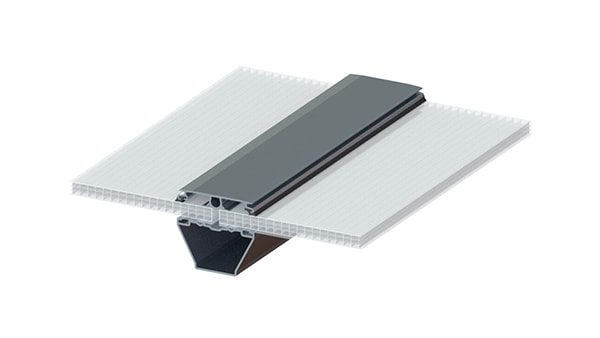

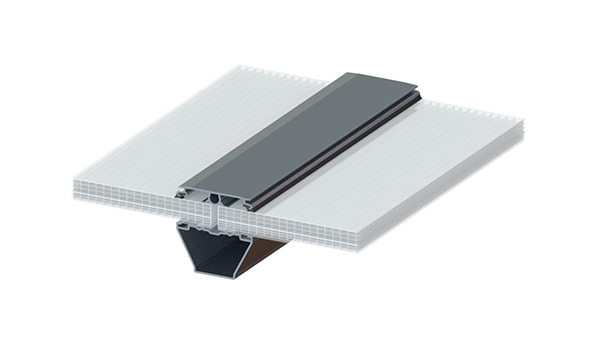

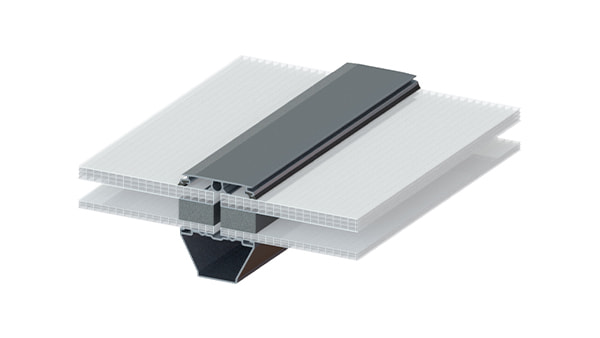

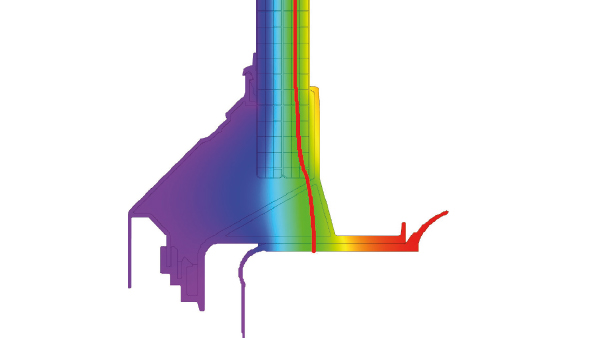

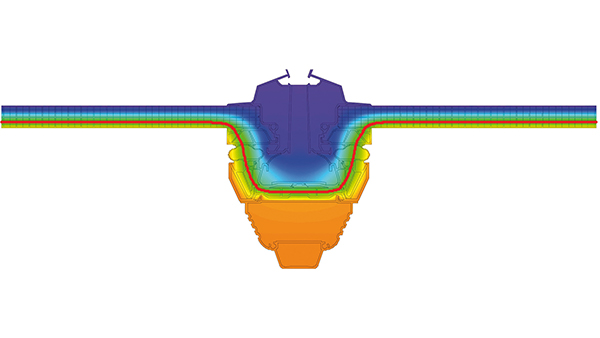

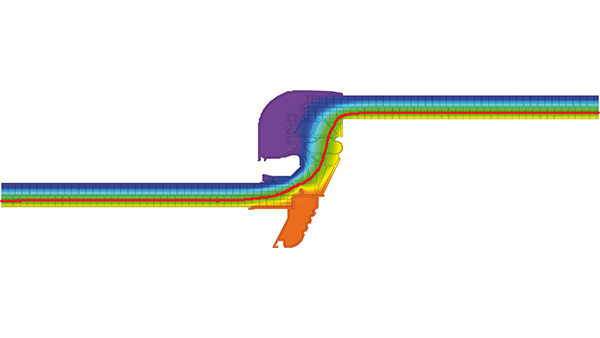

Isothermal load converter – ITL

Effect: The Isothermal Load Converter channels the load on the Continuous Rooflight into the substructure. Since this frees the base profile from loads and tensions, there is no need for metal material. This allows high-quality composite with excellent thermal insulation values to be used for the base profile.

Benefit: The Isothermal Load Converter (ITL) achieves optimised isothermal lines running continuously through the construction and prevents thermal bridges.

Benefit for optimum energy efficiency

- Excellent Uf values in the base profile and even better thermal insulation

- Improved load bearing capacity in the base profile

- Significantly reduced risk of condensation

- Optimised rebate base ventilation

- Smooth interior with few edges which ensures less dirt and grime

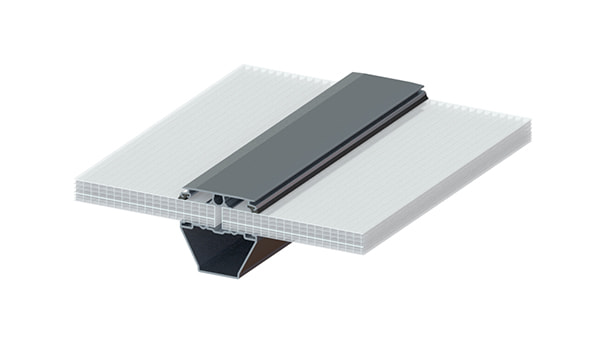

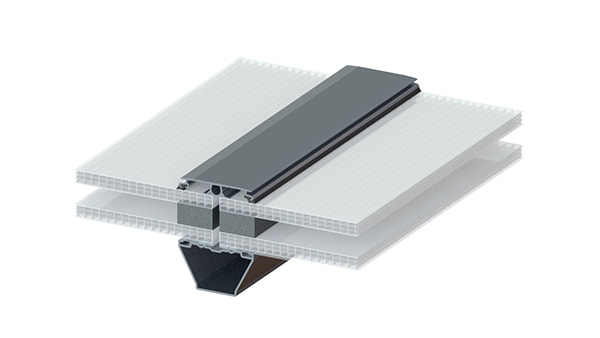

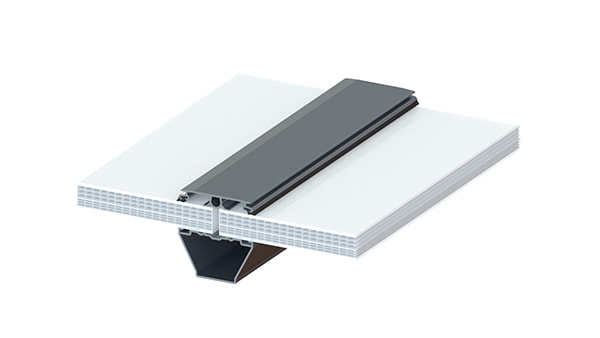

Linear burn-through protection – LBP

Effect: In most cases, the roofing membrane, which is attached to a substructure such as a frame, is pulled up to the upstand and is led under the base profile of the Continuous Rooflight. In the event of a fire inside the building, the roofing membrane on the inside of the upstand will often catch fire and will tend to burn like a “fuse” to the outside of the roof.

Linear Burn-through Protection can be understood as an intelligent system, which restricts the spread of the fire at the roof penetrations. The profile of the Continuous Rooflight plays an important role: It is made of a thermoplastic composite, which softens on the upstand in the event of high temperatures and spreads directly over the burring edge of the roofing membrane. This process seals the burning joints, cutting off the supply of oxygen and extinguishing the flames in the area.

Benefit: The LBP prevents flames from spreading to the roof. Despite it softening at high temperatures, the base profile remains stable during the fire because it is cooled and strengthened by the metal profile of the glazing bead.

LBP – Sophisticated fire protection technology

- Prevents fire from spreading onto the roof through roof penetrations in accordance with specifications in DIN 18232-4

- Patented technology

- No need to place gravel around the Continuous Rooflight

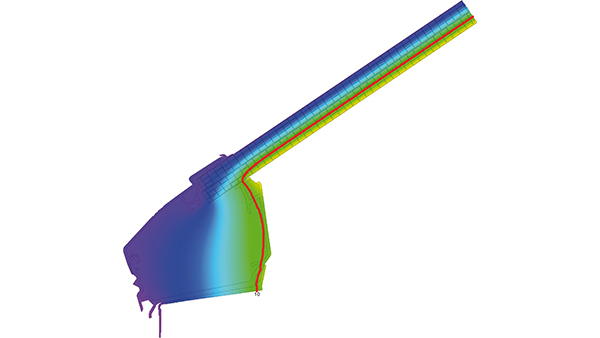

Energy efficiency

Optimised isothermal lines

In the LAMILUX Continuous Rooflight B, the 10°C isothermal line runs consistently through the entire construction. Our guarantee: A minimised risk of condensation forming on the inside of the construction.

The comprehensive thermal protection technology throughout the construction ensures the best Uw values in the European-approved Continuous Rooflight. The energy efficiency properties have been tested and verified in accordance with ETAG 010. This ensures that the consistent insulation properties in the Continuous Rooflight profile are documented. In the event of an order, the Uw values are calculated on a cost-neutral basis, and this calculation is confirmed with the certificate of quality.

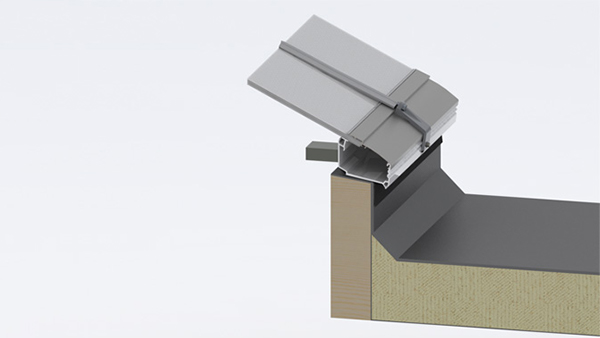

Structural attachment

- Roof mounting variants include mounting on steel sheeting upstands, on wooden trusses or reinforced concrete upstand beams

- Stability is of primary concern with LAMILUX's own steel sheet upstands; LAMILUX complies with the requirements of the German Institute for Building Technology (Deutsches Institut für Bautechnik), according to which sheet steel upstands must be manufactured using high steel grades S 280 GD + Z 275 or S 320 GD + Z 275

- Connection details: Sandwich roof in accordance with IFBS guidelines

Downloads

Continuous rooflight B